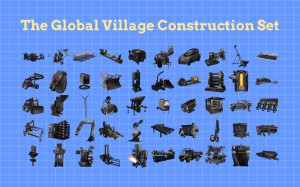

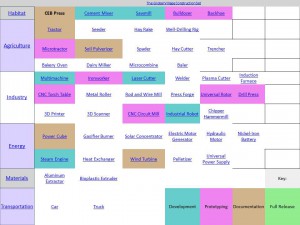

Graphic: Open Source Ecology Global Village Construction Set

#OSE Open Source Everything, Africa, Capabilities-Force Structure, Citizen-Centered, Design, Hardware, Innovation, Manufacturing, Resilience, ResilienceJean Lievens: Chinese Open Source Manufacturing

02 China, 03 Economy, Manufacturing

Chinese business website Caixin Online has a great video on China’s Open Source Hardware Movement, this is an area that promises to change the manufacturing industry.

Open Source is the philosophy of sharing intellectual property and allowing anyone to improve the idea on the proviso they share their changes with the rest of the world.

The hope is that open sourced products end up being more reliable than proprietary designs due to scrutiny from hundreds, or thousands, of reviewers.

Until recently, open source has been largely restricted to the software world but now it’s moving into broader Engineering and manufacturing circles.

As the Caixin video shows, the open source hardware movement is introducing geeks to a tool which many thought was dead – the soldering iron.

I noticed this a week or so ago when I walked into a co-working space and found the lady I was meeting hunched over a soldering iron putting together a part for a quadcopter.

Right now soldering parts to build quadcopters or game controllers is just the beginning, the really interesting things start when open source meets 3D printing – then we’ll see some real game changing things happen.

Jean Lieven: Local Motors Replay — Transformation of Design, Manufacture, and Sale of Personal Transport Vehicles

Crowd-Sourcing, Design, Economics/True Cost, Manufacturing, Money

Alan Moore, Guardian Sustainable Business

22nd May 2013

Local Motors shares its innovations and lets customers be part of the car-building process, while keeping it local.

Last year, I spoke at Shanghai's Radical Design Week about the transformational design of business. I talked about car manufacturing and how, with state of the art 3D fabrication tools, a networked participatory culture and rapid innovation, the car company Local Motors claims to build cars five times faster at one hundred times less the capital cost of conventional manufacturers.

Local Motors is perhaps one of the most comprehensive examples of a revolutionary approach to the design, engineering, manufacturing, sales and marketing of cars. But don't worry if you are not in the automotive industry, the Local Motors story is one about the firms of the future.

Designing high performance organisations

Companies today can change their shape, capability and performance by rethinking and redesigning core processes. In the case of Local Motors, its factories (the Local Motors micro-factory was rated by Jalopnik as one of the world's top 10 most impressive car factories), R&D, sales, marketing and production represents a design system that is an industrial ecology, rather than a series of boxes and silos. Moreover it is much less costly to set up, run and maintain, which enables the company to invest its energies into high quality design and production.

An open networked innovation platform

Local Motors runs competitions to find innovations. For its first vehicle competition, 44,000 designs were submitted and 3,600 innovators shared their knowledge and insights. No one company can hire that many people and there was no cash prize. So, what inspired so many people to participate?

Through its open participatory platform called The Forge, Local Motors has collaborated in automotive innovation with DARPA, the US military research agency, co-designing and building a fully functional prototype of a combat support vehicle in three and a half months. Even large car manufacturers have turned to Local Motors, such as BMW, which is currently running an urban driving experience challenge.

So Local Motors becomes more than just a car manufacturing company – it's an automotive innovation platform and a true community. Local Motors attracts innovators because it is creating and releasing social and intellectual capital into a common pool. This open innovation platform is counter intuitive to many assumptions about how businesses are run, and how intellectual products are created and protected.

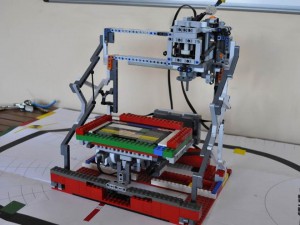

Jean Lievens: Peer production & Modularity — A Lego Experiment

Design, Hardware, Manufacturing

Peer production, modularity & voxels: The RepRap-based, Lego-built 3D printing-milling machine

This research project aims to shed light on the conditions of transferability of Commons-based peer production (CBPP) processes to physical manufacturing. We draw from the political economy of CBPP and its conjunction with digital, desktop manufacturing technologies, the concept of “voxels”, and the case of a hybrid RepRap-based, Lego-built three-dimensional printer-milling machine, to discuss the importance of modular design. We show that modularity, not only in terms of development process but also of hardware components, is necessary to make possible CBPP’s replication for tangible products, decreasing the need for coordination and enabling parallel developments to various directions.

Project page here.

Full title: “Shedding light on the transferability of Commons-based peer production to physical manufacturing: The case of a RepRap-based, Lego-built 3D printing-milling machine”. Vasilis Kostakis and Marios Papachristou. To be submitted.

Jean Lievens: Open Innovation in Food Manufacturing

Economics/True Cost, Innovation, Manufacturing, MaterialsAs White Queen remarked in Lewis Carroll’s immortal story Through the Looking Glass, “…it takes all the running you can do to keep in the same place. If you want to get somewhere else, you must run at least twice as fast as that!” We all run after innovation just as fast as we can and sometimes we feel that it’s all we can do just to stay even with the competition. Sometimes it is good to pause for a moment and reflect on the role of innovation, what we’re doing currently and what we might do differently. The State of Ohio did exactly that in creating the Ohio Third Frontier’s Open Innovation Incentive, which they launched last year.

Open innovation (OI) is the systematic inclusion of parties outside your four walls and outside your existing networks. Companies practice open innovation because they want to reduce the time it takes to get to market, avoid getting trapped by their own thinking, and pursue with agility new opportunities outside their core expertise. Frequently the examples given for open innovation success are things like the iPod™, which wasn’t invented internally at Apple, or the Swiffer™ cleaning system that P&G acquired in its original form from a Japanese company. Those examples can cause one to lose sight of the value OI brings to non-consumer goods companies and to organizations smaller than Apple and P&G.

That was the thinking of the Ohio Third Frontier team when they considered what they could do to support economic growth in the State of Ohio. They recognized that open innovation is an important tool and a way to accelerate economic development in Ohio. The state also recognized that very large companies (greater than $1 billion in annual revenues) were doing this already, while companies in the $10 million to $1 billion range likely needed additional direction and support. They surmised that the expertise needed to incorporate these external technology searches didn’t reside in firms this size and that reliable partners were needed in the form of intermediaries with proven open innovation methods and processes. Thus was born the Ohio Third Frontier Open Innovation Incentive.

Continue reading “Jean Lievens: Open Innovation in Food Manufacturing”

Kalani Kirk Hausman: Quentin Harley released SCARA based “RepRap Morgan” 3D printer and its design

Manufacturing

Quentin Harley released SCARA based “RepRap Morgan” 3D printer and its design

Reprap Morgan is a concentric dual arm SCARA FDM 3D printer, designed and built by Quentin Harley. The SCARA stands for Selective Compliant Assembly Robot Arm or Selective Compliant Articulated Robot Arm. Harley has been working on this project for a couple of years, and in February Harley released pictures showing off the build. The extruder of this Reprap Morgan 3D printer moves along the x and y axes and the bed itself moves along the Z axis. Its major parts, such as the arms, driving gears, pipe adapters are printed on a 3D printer.

. . . . . . . .

“RepRAP Morgan is all about a dream. A dream to make it easy for anyone in South Africa, or anywhere else in the world to build a 3D printer without needing exceedingly expensive materials, hard to find components, stuff that has to be shipped at sometimes more than the cost of the components, requiring advanced tools.” Notes Harley. “Morgan is to be a tool for creation, not a toy or end product. It should be used in education, and must be affordable and safe enough for school kids to use.” adds Harley.