Open Source Hardware: Document the Project from Day One

Hardware

Why you should document your Open Source Hardware project:

This specific moment, that moment when you start working on the refinements of a product to create the second version, could be a great moment to document your invention.

In fact, when you start again the production process, you already know how to do things, and also, you know what are the most complicated moments in the building process and you could leverage on this information to create compelling guidelines for folks interested in replication.

Via Open Electronics.

Continue reading “Open Source Hardware: Document the Project from Day One”

Michel Bauwens: Open Source Energy in France

03 Environmental Degradation, 05 Energy, Design, Economics/True Cost, Hardware

A status report on the Open Source Energy project in France

A contribution from Geoffroy Levy from Nantes:

“A few words about a French project named Open Source Energy. This project is intended to enable the design of open hardware solutions to capture the different kinds of energies available all around us (from the environment or from human activities). A first module to transform and to store electricity from renewable sources is being designed: the ENERCAN (opensourceenergy.wordpress.com/lenercan-v1). This first brick is the starting point of a large scale design process toward the creation of new solutions inspired by old or forgotten ones and improved by the use of high-tech devices. The project is not about large and costly devices but about simple, open and cheap modules that can be replicated to capture every stream of available and lost energies, even the smallest one.

Besides designing the modules, the team took part in several events related to design or DIY in order to promote the project and to share with others.

Continue reading “Michel Bauwens: Open Source Energy in France”

Jean Lievens: Peer production & Modularity — A Lego Experiment

Design, Hardware, Manufacturing

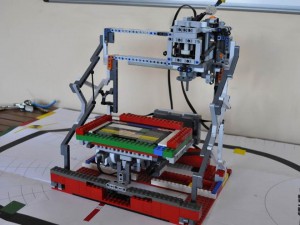

Peer production, modularity & voxels: The RepRap-based, Lego-built 3D printing-milling machine

This research project aims to shed light on the conditions of transferability of Commons-based peer production (CBPP) processes to physical manufacturing. We draw from the political economy of CBPP and its conjunction with digital, desktop manufacturing technologies, the concept of “voxels”, and the case of a hybrid RepRap-based, Lego-built three-dimensional printer-milling machine, to discuss the importance of modular design. We show that modularity, not only in terms of development process but also of hardware components, is necessary to make possible CBPP’s replication for tangible products, decreasing the need for coordination and enabling parallel developments to various directions.

Project page here.

Full title: “Shedding light on the transferability of Commons-based peer production to physical manufacturing: The case of a RepRap-based, Lego-built 3D printing-milling machine”. Vasilis Kostakis and Marios Papachristou. To be submitted.

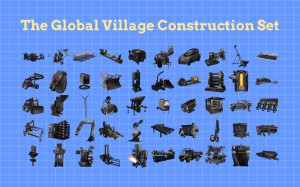

Graphic: Open Hardware Innovation Ecology

Crowd-Sourcing, Design, Economics/True Cost, HardwareJean Lievens: Open Tech Challenges Proprietary, Relocalizes Manufacturing, Addresses Poverty

Crowd-Sourcing, Design, Economics/True Cost, Hardware

Open Tech Forever Challenges Proprietary Innovation

Open source hardware could be a revolutionary tool for unlocking our shackles to profit motivated, proprietary innovation. It has a vision to alleviate poverty through empowering decentralized and affordable, small scale production. Participants anywhere in the world can use the internet to access, improve, or adapt designs for local manufacturing and drastically increase the rate of innovation.

Open Tech Forever (OTF) is emerging to become a new force in open source hardware development by building an open source factory where it will produce open technology. OTF recently launched an Indiegogo crowdfunding campaign to raise $50,000 to build the facility, and they need your support. As a cooperatively-owned social enterprise, all of its innovation will be transparently documented in writing, graphics and video, and released under a Creative Commons license.

OTF’s mission is to “facilitate cooperation among the communities that live on the frontlines of suffering throughout the world, so that we can build enduring solutions to poverty and the destruction of the environment.” OTF co-founder, Aaron Makaruk explains, “An entirely new economic frontier stands before us, a world where innovation and wealth are mass produced as easily as a file is downloaded to a computer. Our goal is to use local, open source factories to outcompete companies that import unsustainable products manufactured in inhuman conditions and put them out of business – one locally-owned, open source company at a time.”

. . . . . . . . .

Relocalizing manufacturing is one of the most significant steps we can take to prepare for the destabilizing effects of climate change and to empower local communities to build resilient, self-sustaining economies. OTF, with its passionate team of skilled engineers and radical mission, will be an exciting project to watch as it grows over the next couple years and a great cause to support through its first phase of development.

Jean Lievin: Micro-Manufacturing and Open Source Everything — Re-Empowering Labor over Capital

#OSE Open Source Everything, Design, Governance, Hardware, Manufacturing, Materials

Micro Manufacturing, Third Wave Style…Perfect for Worker Coops?

In the Next Industrial Revolution, Atoms Are the New Bits

By Chris Anderson

The door of a dry-cleaner-size storefront in an industrial park in Wareham, Massachusetts, an hour south of Boston, might not look like a portal to the future of American manufacturing, but it is. This is the headquarters of Local Motors, the first open source car company to reach production. Step inside and the office reveals itself as a mind-blowing example of the power of micro-factories.

. . . . . . . .

In June, Local Motors will officially release the Rally Fighter, a $50,000 off-road (but street-legal) racer. The design was crowdsourced, as was the selection of mostly off-the-shelf components, and the final assembly will be done by the customers themselves in local assembly centers as part of a “build experience.” Several more designs are in the pipeline, and the company says it can take a new vehicle from sketch to market in 18 months, about the time it takes Detroit to change the specs on some door trim. Each design is released under a share-friendly Creative Commons license, and customers are encouraged to enhance the designs and produce their own components that they can sell to their peers.

. . . . . . . .

Here’s the history of two decades in one sentence: If the past 10 years have been about discovering post-institutional social models on the Web, then the next 10 years will be about applying them to the real world.

This story is about the next 10 years.