Internet Phases: Past, Present, and Future

Jeremiah Owyang

web-strategist.com, 11 June 2013

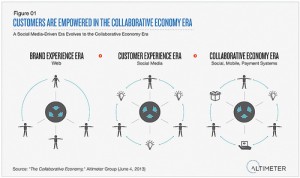

Thanks to you, last week’s report on the collaborative economy was readily received, and has been viewed over 26k times, the media picked up on it, and bloggers alike. As we digest what it means, it’s important to recognize this is the next phase in the internet, and the next phase of social business. An interesting finding is that the second era (social) and the third era (collaborative economy), use the same technologies (social technologies) but instead of sharing media and ideas –people are sharing goods and services. This is all part of a continuum and we need to see our careers progress as the market moves forward with us.

[Social technology enabled the sharing of media and ideas called social business –the same tools enable sharing of goods and services called the collaborative economy]

Internet Phases: Past, Present, and Future

| Attribute | Brand Experience Era | Customer Experience Era | Collaborative Economy Era |

| Driving technology | CMS and HTML | Social Technologies | Social Technologies |

| Years | 1995: Internet had 14% american adoption | 2005: Business blogging disrupted corporations | 2013: AirBnb, TaskRabbit, Lyft, gain mainstream attention |

| What is shared | Vetted Information | Personal Ideas and Media | Goods and Services |

| Who shares | Few | Many | Many |

| Who receives | Many | Many | Many |

| What it looks like | Brands and media talk, people listen | Everyone talks and listens | Buy once, share many, need to buy less |

| Who has the power | Brands and publishers | Those who use social | Those who share goods and services |

| Who is disrupted | Traditional mediums: TV, Print | Corporations, governments | Corporations, governments |

| What must change | Media models | Communication and marketing strategy | Business models |

| How corporations responded | Created their own corporate website | Adopted social tools internally, externally | Learn to share products, enable marketplace |

| Software needed | CMS and design tools | SMMS, monitoring, communities | Marketplace, ecommerce, communities, SMMS, Monitoring |

| Services needed | User Experience, Design, Content | Social strategy, community managers, communicators | Agencies that help with trust, customer advocates, ? |

| Who wins | Those who adopt | Those who adopt | Those who adopt |

What it means to your career, clients, and company:

Continue reading “Jean Lievens: Internet Phases: Past, Present, and Future”